Engraving is a simple, yet quick process, but it makes the jewelry priceless. There are different processes that jewelers can choose to engrave their pieces. Understanding engraving and its processes can help you figure out which option is the best for the pieces that you create. This basic guide will walk you through what engraving is, the different types of engraving, and the different types of materials that you can engrave.

What Exactly Is Engraving?

Engraving is the action of marring the surface of an object in order to create a design on the object. Unlike other types of marking, such as laser marking, when you engrave an object you can feel where the surface has been marred. Engraving is permanent and can be highly detailed and precise.

Engraving processes have become extremely advanced so that most jewelers can easily engrave very complicated, custom designs onto their jewelry. You have the ability to program any custom design that you want into a computer that will then control the engraver to create precise engravings according to the custom design. Because of the computer-controlled process, jewelers can feel confident that their engraving will look exactly the way that they want it to.

Different Kinds of Jewelry Engraving

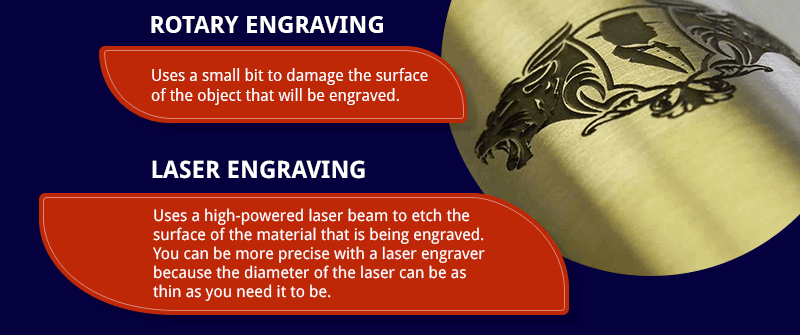

There are benefits to choosing either rotary engraving or laser engraving for your jewelry engraving. Once you understand more about the different types of engraving you can figure out the best type of engraving for the jewelry you would like to be customized.

Rotary Engraving

Rotary engraving uses a small bit to damage the surface of the object that will be engraved. Any hand engraving is done with a traditional rotary engraving tool, however, there are also mechanical rotary engraving tools where the design is programmed into the computer and then etched onto the surface according to the design that is programmed.

There are some drawbacks however to traditional rotary engraving. While rotary engraving can be very precise, the design of the engraving can only be as thin as the bit itself. Also, the bit itself needs to be replaced when it gets worn out. It also tends to take a little longer to do traditional rotary engraving.

The largest drawback of traditional engraving is that it cannot be used on certain materials. Traditional rotary engraving cannot be used on delicate items that are sensitive to heat or pressure. You will not be able to engrave any jewelry that is made with plastic or glass, because those materials can easily be damaged or broken with rotary engraving.

Laser Engraving

Laser engraving uses a high-powered laser beam to etch the surface of the material that is being engraved. Similar to the mechanical rotary engraving machine, the design that you want is programmed into the computer and the machine will engrave the design that you want into the jewelry. However, you can be more precise with a laser engraver because the diameter of the laser can be as thin as you need it to be. Also, the intensity of the laser can determine how deep the engraving will be.

Unlike the traditional rotary engravers, you don’t need to worry about the materials that it can engrave. Laser engravers can be uses for materials that are extremely sensitive, such as paper. While paper is not a common material to make jewelry with, it is good to know that no matter what materials you want to engrave, they can be customized with laser engraving.

Also, unlike rotary engraving, there are fewer accessories, such as drill bits, that will need to be replaced when they are worn out. So if you want to do your own engravings rather than hiring an engraving company, consider a laser engraver as there is much less upkeep than a rotary engraver.

Different Types of Materials that Can Be Engraved

One of the benefits of modern engraving machines is that you have a variety of choices of materials that can be engraved. This is especially beneficial for jewelers because it means that they are not confined to using specific materials for their jewelry.

Metals

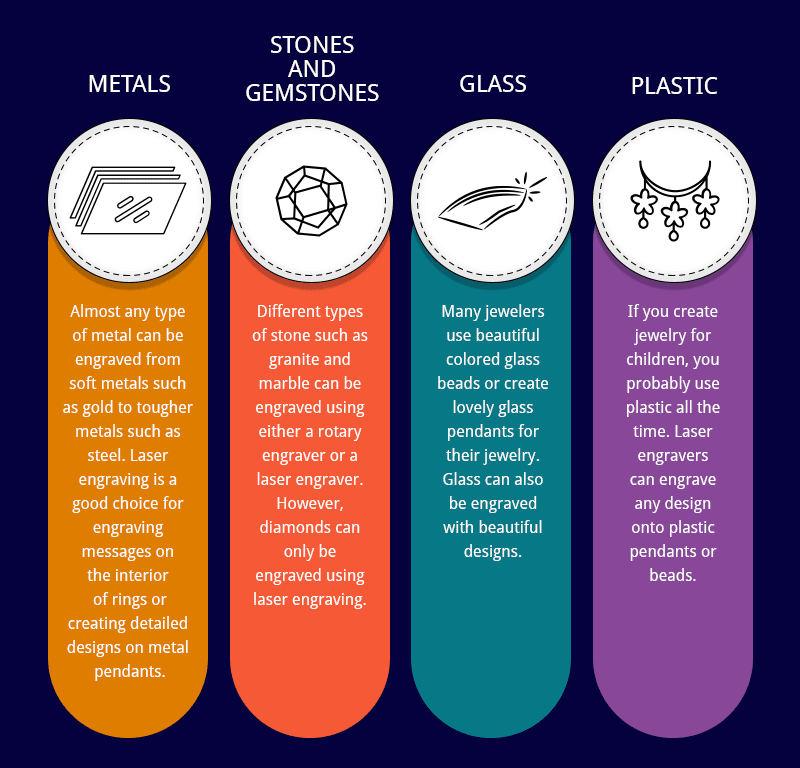

Almost any type of metal can be engraved from soft metals such as gold to tougher metals such as steel. Metal engraving machines, such as a laser engraver, is able to penetrate the metals and create the design that any jeweler would want on the metal. Laser engraving is a good choice for engraving messages on the interior of rings or creating detailed designs on metal pendants.

Stones and Gemstones

Different types of stone such as granite and marble can be engraved using either a rotary engraver or a laser engraver. However, for semi-precious stones and gemstones we recommend that you only use a laser engraver. The laser engraver is so precise that you will be able to get the exact design that you want on it without needing to worry about any errors. Also, there are some gems, such as diamonds, that can only be engraved using laser engraving.

Glass

Many jewelers use beautiful colored glass beads or create lovely glass pendants for their jewelry. Glass can also be engraved with beautiful designs. However, as we stated before, traditional rotary engraving on glass is not the best idea. Since glass is so brittle and is susceptible to pressure, rotary engraving will often crack the glass or will chip off a piece of the glass that the jeweler did not want to be removed. With laser engraving, jewelers don’t need to worry about cracking or the glass breaking. The laser will be able to engrave the exact design you want without damaging the glass.

Plastic

While many fine jewelers don’t really use much plastic in their pieces, if you create jewelry for children, you probably use plastic all the time. Laser engravers can engrave any design onto plastic pendants or beads. We would not recommend that you use rotary engraving for plastic, as the friction of the bit on the plastic will create heat, which could melt the plastic and ruin the design.

Using Laser Engravers for Your Jewelry Engraving

For jewelry makers, laser engraving operations can either be performed in-house or outsourced to a third-party engraving company. Both options achieve a similar result—an engraved jewelry piece—but are appropriate for different situations.

Laser Engravers

In-house engraving operations necessitate investment in laser engravers, such as a CO2 or fiber laser engraving and marking system, for use within the facility. While costly, the equipment allows you to create custom engraved designs at little to no additional cost. This option is suitable for jewelry making operations where custom engravings are a regular occurrence.

Laser Engraving Services

Outsourced engraving operations require you to partner with a separate laser engraving company. In doing so, you avoid having to spend money on purchasing a laser engraver and can trust that the engraving will meet your specifications. This option is ideal for jewelry making operations where bulk orders are common and little to no custom engraving design work is required.

Are You Ready for a Free Quote?

Interested in Engraving for Other Applications?