Throughout the years, new developments in manufacturing techniques and technologies have enabled industrial and commercial manufacturers to achieve better precision and accuracy at a lower cost. One of the most revolutionary pieces of manufacturing equipment developed in recent years is the laser. After the construction of the first working laser in 1960, the technology continued to advance, eventually turning into one of the most effective and efficient tools for cutting, engraving, and marking workpieces. Today, it is used on a wide range of materials to cut a variety of shapes and engrave and mark an array of standard and custom designs.

At Hai Tech Lasers, Inc., we are pleased to offer custom laser cutting services to customers in Los Angeles and beyond. We also provide laser engraving, laser marking, and laser etching capabilities. Equipped with over 30 years of industry experience and a broad selection of laser machines, we have the knowledge, skills, and tools to handle virtually any laser cutting, engraving, or marking need.

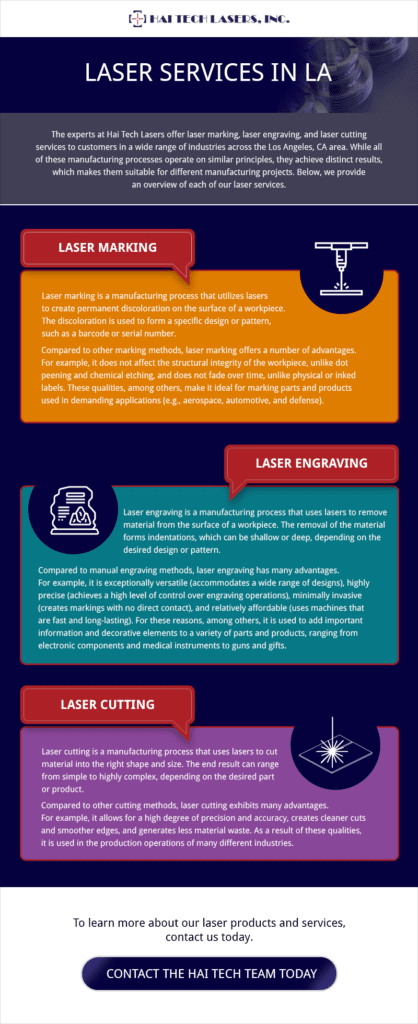

The experts at Hai Tech Lasers offer laser marking, laser engraving, and laser cutting services to customers in a wide range of industries across the Los Angeles, CA area. While all of these manufacturing processes operate on similar principles, they achieve distinct results, which makes them suitable for different manufacturing projects. Below, we provide an overview of each of our laser services.

The experts at Hai Tech Lasers offer laser marking, laser engraving, and laser cutting services to customers in a wide range of industries across the Los Angeles, CA area. While all of these manufacturing processes operate on similar principles, they achieve distinct results, which makes them suitable for different manufacturing projects. Below, we provide an overview of each of our laser services.

Laser marking is a manufacturing process that utilizes lasers to create permanent discoloration on the surface of a workpiece. The discoloration is used to form a specific design or pattern, such as a barcode or serial number.

Compared to other marking methods, laser marking offers a number of advantages. For example, it does not affect the structural integrity of the workpiece, unlike dot peening and chemical etching, and does not fade over time, unlike physical or inked labels. These qualities, among others, make it ideal for marking parts and products used in demanding applications (e.g., aerospace, automotive, and defense)

Laser engraving is a manufacturing process that uses lasers to remove material from the surface of a workpiece. The removal of the material forms indentations, which can be shallow or deep, depending on the desired design or pattern.

Compared to manual engraving methods, laser engraving has many advantages. For example, it is exceptionally versatile (accommodates a wide range of designs), highly precise (achieves a high level of control over engraving operations), minimally invasive (creates markings with no direct contact), and relatively affordable (uses machines that are fast and long-lasting). For these reasons, among others, it is used to add important information and decorative elements to a variety of parts and products, ranging from electronic components and medical instruments to guns and gifts.

Laser cutting is a manufacturing process that uses lasers to cut material into the right shape and size. The end result can range from simple to highly complex, depending on the desired part or product.

Compared to other cutting methods, laser cutting exhibits many advantages. For example, it allows for a high degree of precision and accuracy, creates cleaner cuts and smoother edges, and generates less material waste. As a result of these qualities, it is used in the production operations of many different industries.

The laser marking, laser engraving, and laser cutting processes accommodate a variety of materials. Below, we outline the materials we typically utilize in our operations.

The laser marking process can be used to mark a wide range of substrates. One thing to keep in mind is that the markings are created by discoloring the surface. As a result, it is best to pick a material that forms high-contrast discolorations as markings on it will be easier to view.

Some of the materials we laser mark include:

The laser engraving process can create engravings on many materials. While the engravings are permanent, they can experience wear over time, which makes them harder to view. This effect is more apparent in softer materials (e.g., leather) than in harder materials (e.g., hardwood). However, in general, laser engravings last much longer than engravings made by other methods regardless of the material.

Some of the materials we laser engrave include:

The laser cutting process is suitable for cutting various materials. However, they must be able to withstand the heat of the laser without deforming or metal.

Some of the materials we laser cut include:

Compared to other manufacturing technologies, laser technology allows for better precision and accuracy, faster processing speeds, lower waste generation, and many other advantages. These qualities, among others, make it well-suited for the production of a variety of parts and products. Typical components made using laser cutting, laser engraving, and/or laser marking include:

Hai Tech Laser is a premier provider of industrial laser cutting, engraving, and marking services based in Santa Clarita, California. This convenient location, combined with our extensive industry experience and state-of-the-art laser job shop, makes us the ideal partner for all laser cutting, engraving, and marking needs in the Los Angeles area and beyond. Our expertise and equipment ensure customers receive parts and products that fully meet their specifications and standards, while our local facility location ensures they receive them with quick turnaround times.

In addition to our laser services, we also offer industrial laser equipment. We supply laser marking and engraving systems to customers who want to perform the work themselves. Additionally, we repair and upgrade equipment to ensure it continues to operate as needed.