Laser marking enables product manufacturers to add precision colors and shapes onto a variety of worked surfaces. It is a contact-free coloring process used to quickly create indelible marks on smooth or polished surfaces. Laser marking tools provide a wide variety of colors and tones to create an exact, appealing finish.

This page will discuss how laser markers work and the advantages of the process, the material surfaces laser marking works best on different industries that benefit from laser marking, the various types of laser marking systems, and the extensive laser marking capabilities here at Hai Tech Lasers.

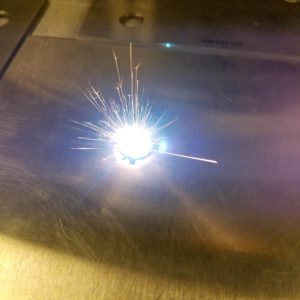

Laser marks and laser etchings are permanent. In general, the lasers will apply concentrated heat to the surface to remove, discolor, or otherwise affect the top layer of the material to create finely controlled, high-contrast marks. Many lasers feature varying wavelength and power level capabilities to facilitate a wide variety of marks or to allow marking on a wider variety of materials.

There are multiple laser marking methods available. Some of the most popular laser marking processes include:

While laser marking is just one of the color marking techniques available, it’s one of the most advantageous. Not only can the techniques be applied to a wide variety of surface materials, but each one also creates appealing patterns and graphics that appeal to consumers in highly competitive product markets.

Some of the key advantages of laser marking include:

Since laser marking equipment can use a wide variety of lasers with even wavelengths to generate heat or power, they can create high-contrast marks on almost any surface type. The lasers can also be finely controlled to create highly detailed and accurate marks like barcodes.

Laser marks are permanent and they last as long as the surface does. This is essential in extreme environments, such as environments with chemical exposure, salt water, and extreme heat or wear, where labels and paint won’t last. Laser marks have been thoroughly tested under exposure to salt spray, UV rays, and other adverse conditions to ensure the longevity of the marks.

Laser equipment creates even, detailed marks very quickly. Automated laser marking machines handle high-volume production demands with extremely short cycle times.

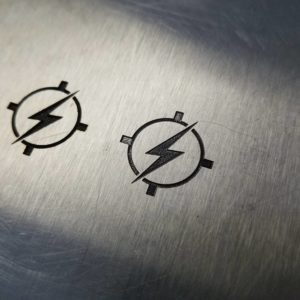

The lasers used in laser marking processes are built to last in extreme and industrial environments. The lasers can generate marks with extreme precision so companies can ensure their products have clear instructions, easy-to-read safety instructions, and quickly recognizable logos. Laser marking machines can even create fonts as small as one point.

Lasers follow the same set of precise instructions over and over again with limited human intervention, resulting in highly efficient production cycles—especially for high-volume orders. The process is also more efficient than additive processes such as labeling, which require additional materials to mark items. Etching and removal processes that take material away from the substrate only remove an insignificant amount.

Laser marking devices work with a wide variety of substrates, including both metal and non-metal materials. Materials that are frequently laser marked include:

Many laser marking techniques can be used on both plastic and metal. However, unlike metal, plastic can benefit from foaming processes to provide slightly raised or textured markings on the surface. This reaction doesn’t occur in metal substrates.

At Hai Tech Lasers, we’re proud to serve the following industries:

Aerospace manufacturers benefit from the permanent nature of laser marks. The different processes can create indelible barcodes and serial numbers that permanently identify each component or device. Another advantage of laser marking is that safety information marked onto the parts can’t wear away.

Automotive manufacturers also benefit from being able to permanently etch serial numbers and Vehicle Identification Numbers onto parts and completed vehicles. Through laser marking, automotive companies can also etch popular logos onto metal, plastic, and leather surfaces.

Even microscopic electronic components need identifiers. Laser marked identification codes, serial numbers, and barcodes can be marked onto small or fragile electronic parts because the lasers don’t damage the surrounding surface and can create very small marks.

Precisely designed medical devices and implants benefit from laser marks because they don’t introduce additional materials to the product surface. This is especially important for medical implants. Laser marked graphics and numbers on medical devices such as surgical tools can also lay flat against the surface without changing the texture, leading to fewer sterilization errors or the risk of cross-contamination.

Defense manufacturers need to be able to clearly mark equipment, components, and products to facilitate organized handling around the world. Safety information or instructions also need to be able to withstand abrasion, extreme temperatures, wear and tear, and saltwater exposure in marine environments. Laser marks perform where labels can’t.

At Hai Tech Lasers, we specialize in using high-quality laser marking machines that fit our clients’ unique needs. We have CO2, crystal, UV, and fiber lasers to be able to laser mark nearly any material the customer brings in. Hai Tech Lasers offers the following laser marking services to our clients:

Laser marks are permanent, precise, and highly visible. Manufacturers can use laser marking systems to put barcodes serial numbers, and instructions on product surfaces to ensure the marks never fade or wear away. Contact Hai Tech Lasers today to find the right laser marking equipment for your next project.