At Hai Tech Lasers, Inc., we offer precision laser cutting services to customers in a diverse set of industries. The process enables us to cut precise and accurate shapes from a variety of metals, including aluminum.

Below, we provide an overview of the aluminum laser cutting process, including what it is, the benefits of using aluminum, and the typical applications of laser cut aluminum.

Laser cutting is a non-contact, thermal-based manufacturing process. It uses laser technology—rather than machine tools—to heat, melt, and remove localized areas of the workpiece to form the desired cuts. Due to its excellent accuracy and precision, it can be used to produce simple and highly complex components from various metal and non-metal materials, including aluminum.

Aluminum is strong, lightweight, and corrosion resistant, which makes it suitable for the manufacture of many parts and products. While manufacturers can cut it using laser technology, they must overcome a few challenges. One of the main issues faced when cutting aluminum is its reflectivity. As it is highly reflective, there is a risk of the laser beam reflecting back toward the equipment and damaging it. The other main issue is the material’s thermal conductivity. Since it readily conducts heat, much of the energy from the laser is transferred laterally through the material, resulting in lower cutting efficiency and slower cutting speeds. Both problems can be avoided by using the right equipment setup and cutting parameters. For example, using higher-power lasers alongside compressed gas systems can improve cutting capacities and edge finish quality.

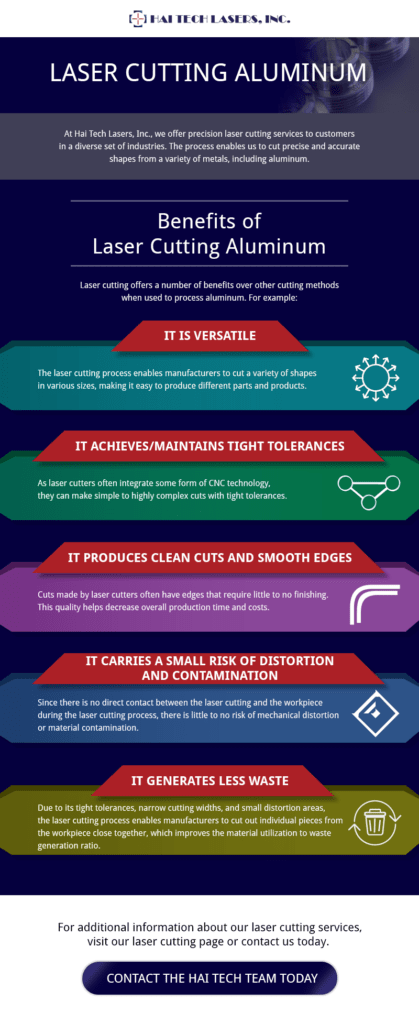

Despite the above challenges, laser cutting offers a number of benefits over other cutting methods when used to process aluminum. For example:

Despite the above challenges, laser cutting offers a number of benefits over other cutting methods when used to process aluminum. For example:

Aluminum is used to manufacture components for a wide range of industries and applications. Examples of typical laser cut aluminum parts and products include:

Looking for the ideal laser fabrication partner for your aluminum laser cutting needs? Turn to the experts at Hai Tech Lasers! For additional information about our laser cutting services, visit our laser cutting page or contact us today. To discuss your specific laser cutting requirements with one of our team members, request a quote.