The development of laser technology has progressed over time in terms of its applications and effectiveness. Today’s fiber lasers can produce over a thousand watts with consistent properties and functionality. Furthermore, the fiber allows bending and coiling, producing more space-efficient, high-quality, and compact beams.

Due to the broad range of available power outputs, fiber lasers are effectively used in various industries. These include the material processing, telecommunications, spectroscopy, medical, and optical sectors.

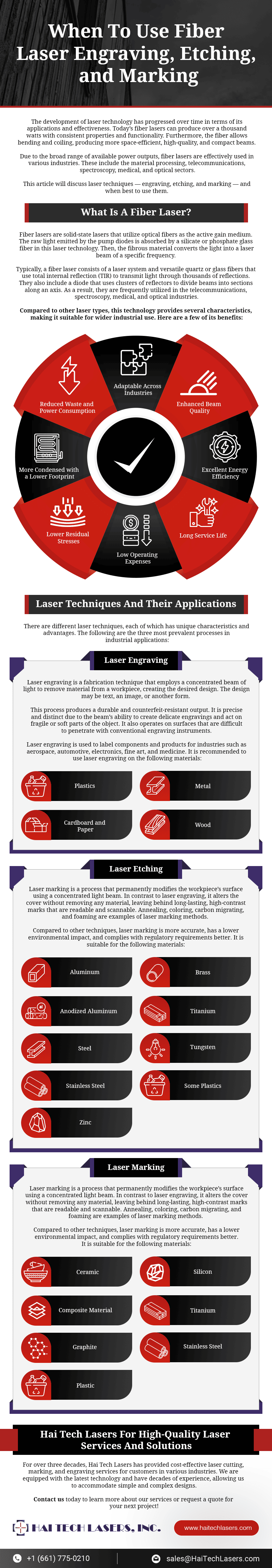

This article will discuss laser techniques — engraving, etching, and marking — and when best to use them.

What Is a Fiber Laser?

Fiber lasers are solid-state lasers that utilize optical fibers as the active gain medium. The raw light emitted by the pump diodes is absorbed by a silicate or phosphate glass fiber in this laser technology. Then, the fibrous material converts the light into a laser beam of a specific frequency.

Typically, a fiber laser consists of a laser system and versatile quartz or glass fibers that use total internal reflection (TIR) to transmit light through thousands of reflections. They also include a diode that uses clusters of reflectors to divide beams into sections along an axis. As a result, they are frequently utilized in the telecommunications, spectroscopy, medical, and optical industries.

Compared to other laser types, this technology provides several characteristics, making it suitable for wider industrial use. Here are a few of its benefits:

- Adaptable across industries

- Enhanced beam quality

- Excellent energy efficiency

- Long service life

- Low operating expenses

- Lower residual stresses

- More condensed with a lower footprint

- Reduced waste and power consumption

Laser Techniques and Their Applications

There are different laser techniques, each of which has unique characteristics and advantages. The following are the three most prevalent processes in industrial applications:

Laser Engraving

Laser engraving is a fabrication technique that employs a concentrated beam of light to remove material from a workpiece, creating the desired design. The design may be text, an image, or another form.

This process produces a durable and counterfeit-resistant output. It is precise and distinct due to the beam’s ability to create delicate engravings and act on fragile or soft parts of the object. It also operates on surfaces that are difficult to penetrate with conventional engraving instruments.

Laser engraving is used to label components and products for industries such as aerospace, automotive, electronics, fine art, and medicine. It is recommended to use laser engraving on the following materials:

- Plastics

- Cardboard and paper

- Metal

- Wood

Laser Etching

Laser etching creates marks on components and products by melting their outer layer. It is a versatile technique that can be applied to most metals. The process starts when the laser beam delivers a large amount of energy to a small area, producing a raised mark. Consequently, the material’s surface melts and expands.

This technique is highly recommended when you are producing permanent markings — such as data matrix codes, serial numbers, barcodes, and logos — on the following metals:

- Aluminum

- Anodized aluminum

- Steel

- Stainless steel

- Zinc

- Brass

- Titanium

- Tungsten

- Some plastics

Laser Marking

Laser marking is a process that permanently modifies the workpiece’s surface using a concentrated light beam. In contrast to laser engraving, it alters the cover without removing any material, leaving behind long-lasting, high-contrast marks that are readable and scannable. Annealing, coloring, carbon migrating, and foaming are examples of laser marking methods.

Compared to other techniques, laser marking is more accurate, has a lower environmental impact, and complies with regulatory requirements better. It is suitable for the following materials:

- Ceramic

- Composite material

- Graphite

- Plastic

- Silicon

- Titanium

- Stainless Steel

Hai Tech Lasers for High-Quality Laser Services and Solutions

For over three decades, Hai Tech Lasers has provided cost-effective laser cutting, marking, and engraving services for customers in various industries. We are equipped with the latest technology and have decades of experience, allowing us to accommodate simple and complex designs.

Contact us today to learn more about our services or request a quote for your next project!