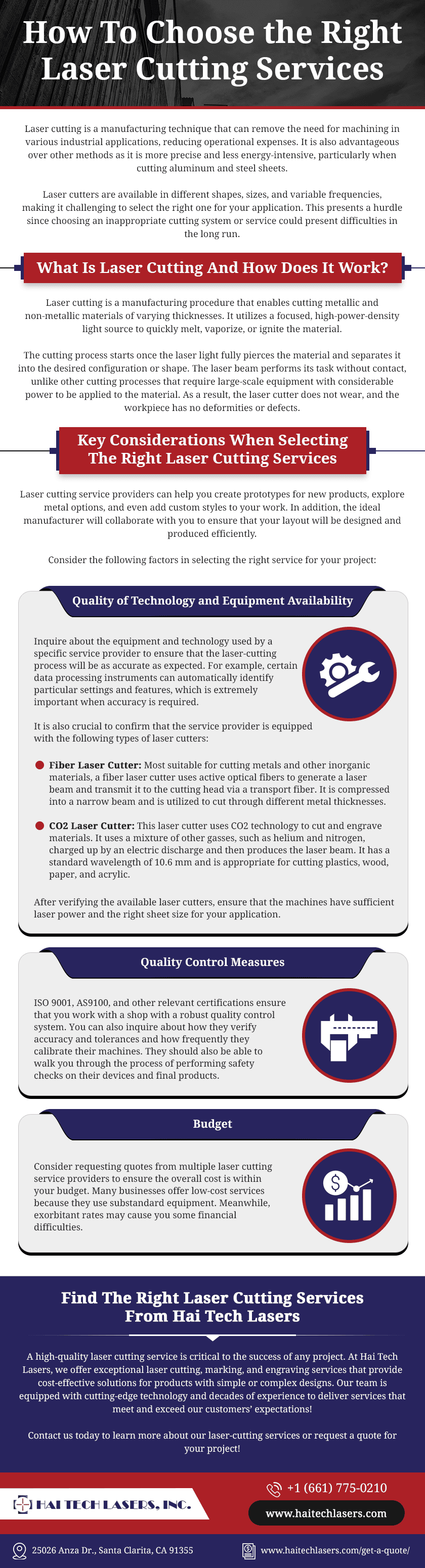

Laser cutting is a manufacturing technique that can remove the need for machining in various industrial applications, reducing operational expenses. It is also advantageous over other methods as it is more precise and less energy-intensive, particularly when cutting aluminum and steel sheets.

Laser cutters are available in different shapes, sizes, and variable frequencies, making it challenging to select the right one for your application. This presents a hurdle since choosing an inappropriate cutting system or service could present difficulties in the long run.

This article will look at the laser-cutting process and the key considerations when selecting the right services.

What Is Laser Cutting and How Does It Work?

Laser cutting is a manufacturing procedure that enables cutting metallic and non-metallic materials of varying thicknesses. It utilizes a focused, high-power-density light source to quickly melt, vaporize, or ignite the material.

The cutting process starts once the laser light fully pierces the material and separates it into the desired configuration or shape. The laser beam performs its task without contact, unlike other cutting processes that require large-scale equipment with considerable power to be applied to the material. As a result, the laser cutter does not wear, and the workpiece has no deformities or defects.

Key Considerations When Selecting the Right Laser Cutting Services

Laser cutting service providers can help you create prototypes for new products, explore metal options, and even add custom styles to your work. In addition, the ideal manufacturer will collaborate with you to ensure that your layout will be designed and produced efficiently.

Consider the following factors in selecting the right service for your project:

Material To Be Cut

It is critical to consider the type of material you want to cut, its thickness, and its density. Laser cutting can handle a variety of materials, including the following:

- Paper

- Wood (plywood, maple, MDF – medium-density fibreboard)

- Acrylic (extruded and cast acrylic)

- Metals

- Plastics

However, not all cutters will be able to handle your thickness and density requirements. For example, certain equipment can cut metals such as mild steel, stainless steel, and non-ferrous metals, but it is significantly more difficult to process reflective metals like aluminum. Similarly, laser cutting is not recommended for cutting glass. Since this material is reflective, there is a higher power demand on the equipment.

Furthermore, woods containing oils and resins are not suitable because they are prone to catching fire and causing spontaneous combustion.

Quality of Technology and Equipment Availability

Inquire about the equipment and technology used by a specific service provider to ensure that the laser-cutting process will be as accurate as expected. For example, certain data processing instruments can automatically identify particular settings and features, which is extremely important when accuracy is required.

It is also crucial to confirm that the service provider is equipped with the following types of laser cutters:

- Fiber laser cutter: Most suitable for cutting metals and other inorganic materials, a fiber laser cutter uses active optical fibers to generate a laser beam and transmit it to the cutting head via a transport fiber. It is compressed into a narrow beam and is utilized to cut through different metal thicknesses.

- CO2 laser cutter: This laser cutter uses CO2 technology to cut and engrave materials. It uses a mixture of other gasses, such as helium and nitrogen, charged up by an electric discharge and then produces the laser beam. It has a standard wavelength of 10.6 mm and is appropriate for cutting plastics, wood, paper, and acrylic.

After verifying the available laser cutters, ensure that the machines have sufficient laser power and the right sheet size for your application.

Quality Control Measures

ISO 9001, AS9100, and other relevant certifications ensure that you work with a shop with a robust quality control system. You can also inquire about how they verify accuracy and tolerances and how frequently they calibrate their machines. They should also be able to walk you through the process of performing safety checks on their devices and final products.

Budget

Consider requesting quotes from multiple laser cutting service providers to ensure the overall cost is within your budget. Many businesses offer low-cost services because they use substandard equipment. Meanwhile, exorbitant rates may cause you some financial difficulties.

Find the Right Laser Cutting Services From Hai Tech Lasers

A high-quality laser cutting service is critical to the success of any project. At Hai Tech Lasers, we offer exceptional laser cutting, marking, and engraving services that provide cost-effective solutions for products with simple or complex designs. Our team is equipped with cutting-edge technology and decades of experience to deliver services that meet and exceed our customers’ expectations!

Contact us today to learn more about our laser-cutting services or request a quote for your project!