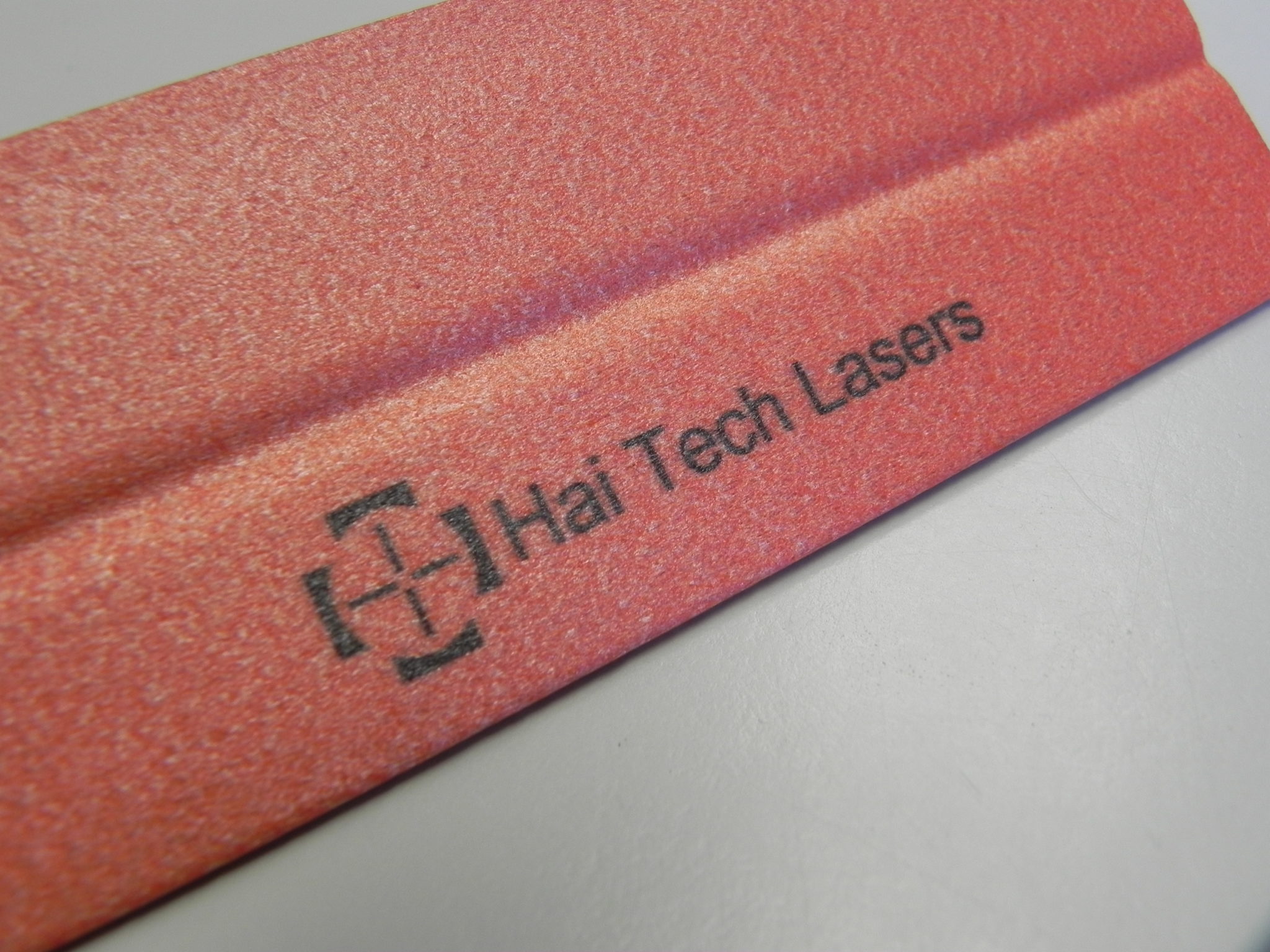

Plastic and thermoplastic products and components have become integral parts of industrial and commercial applications. Like metal products, plastic components also need to be cut, marked, and engraved. Hai Tech Lasers, Inc. provides the solutions with state-of-the-art laser systems. We offer plastic laser engraving and marking services that can provide huge benefits to your company’s product identification and tracking efforts.

Plastic and thermoplastic products and components have become integral parts of industrial and commercial applications. Like metal products, plastic components also need to be cut, marked, and engraved. Hai Tech Lasers, Inc. provides the solutions with state-of-the-art laser systems.

Laser marking uses a plastic laser engraver to create permanent or semi-permanent marks on various components. It is a non-contact, non-subtractive process, meaning it does not directly contact the object and does not remove plastic from the surface. This reduces the risk of structural integrity loss and mechanical deformation. Alternatively, the method uses a laser to produce discolorations in localized parts of the laser-etched plastic’s surface in distinct patterns and shapes to form markings such as serial numbers and designs, e.g., barcodes.

At Hai Tech, we utilize two types of laser marking techniques to create precise, aesthetically-appealing markings on a variety of goods and products:

Laser marking technology has seen rapid adoption across different industries due to its precision and reliability. Here are some of the benefits pushing the growth of the laser marking plastic industry.

Due to high adoption in diverse sectors, laser marking plastic has many applications, including product traceability, automotive decoration, and secured ID cards. Other applications of laser marking plastic include:

Most plastics and thermoplastics can be easily laser marked, but there are some plastics that do not exhibit color changes when exposed to infrared lasers. However, these plastics can be modified with a suitable additive to allow laser marking capabilities. Below are some of the common plastic materials suitable for laser marking:

The right type of laser system can provide immense benefits to product marking and engraving processes. To ensure that we meet the various needs of our customers, we offer the following systems for permanent laser marking on plastics:

With laser marking technologies as the foundation, and the various benefits they provide to varying industries, Hai Tech Lasers’ plastic marking systems provide optimum solutions for marking and engraving a diverse range of plastics. We have perfected the art of industrial laser marking and laser engraving over 30 years of delivering systems to companies in industries such as medical, automotive, aerospace, and more. Contact us today to request a quote.